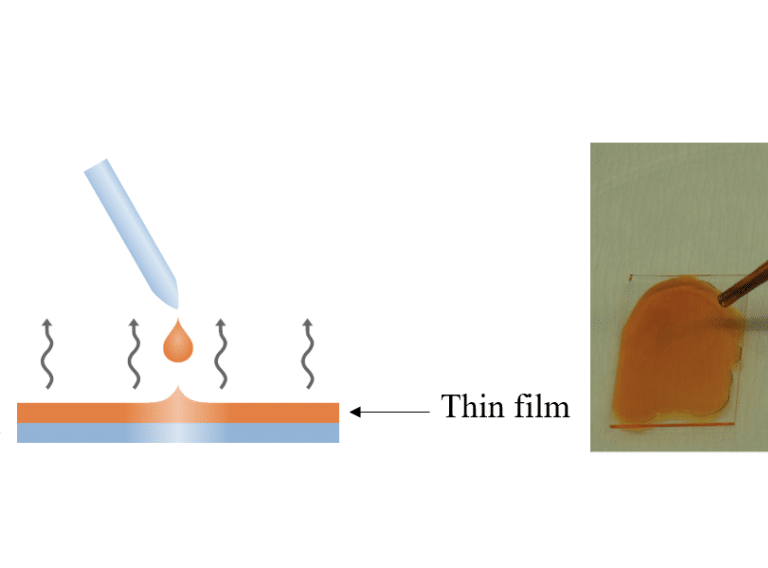

drop casting method

Depending on the depth a 316- or 14-ounce weight kept the sinker ticking lightly over the bottom. It requires a very small amount of solvent.

Solvent Casting Technique Drop Casting Method Dip Coating Technique Film Casting Technique Polymer Coatings Technologies And Applications

This method is advantageous since the thickness of the polymer-coated film on the electrode can be known from the original concentration of polymer solution and droplet volumeThis technology is rather simple and there is no waste of material.

. Drop-casting is a simple cheap method and permits the formation of a monolayer over a large area. Combination of solvents Solvents evaporation time. Make a bubble of liquid on top of a surface then either.

In principle film thickness depends on the volume of dispersion used and the particle concentration both of which can be easily varied. A second polymer solution is added and dispersed in the second mixture to prepare a third mixture. Up to 10 cash back Drop-casting is another simple and low-cost deposition method for the fabrication of small-area films3 Drop-casting relies on the release of large droplets with controlled sizes and momentum that spread and wet the surface upon impact.

Casting is the oldest metal processing process that first melting metals into liquid status then pouring metal liquid in injection moulds and cooling a while to obtain the required shape or dimensions. Dependent on many controllable parameters dωdt ω t solution viscosity. Deposition techniques Drop casting Spin coating Dip coating Layer-by-layer.

Drop Casting Dropping of solution and spontaneous solvent evaporation Evaporation Dropping. After casting upstream VanDam let the current usher his drop shot rig downstream. Multiple droplets formed using this method provide a distinctive environment to control the shrinkage direction and the evaporation rate of the droplets Liu et al 2014.

Drop coating The thickness of the film obtained is directly proportional to the concentration of the nanocomposite solution or suspension. When products are not suitable for forging casting is the economic method for blank shape. Quickly load your rod cast 4 to 5 feet past the fish.

Wait 30 seconds and rinse with clean solvent or. This method is widely used because of low costs shorter preparation time and most importantly easy variation in reaction conditions. In this paper we report on the fabrication of a large-area monolayer of SiO 2 NPs 50 nm in diameter with a high surface coverage on top of a silicon substrate using a drop.

Start in the ready position with the fly in hand and plenty of fly line un-spooled from the reel. In this video I show you how to create simple silver drop castings with simple tools. In the present work drop-casting was used to prepare films for screening two-dimensional Ruddlesden-Popper 2DRP metal-halide perovskite formulations for potential utility in PSCs without additional processing steps such as inert-gas.

A first polymer solution is added and dispersed in the first mixture to prepare a second mixture. In this method a drop of liquid containing a suspension of the particles of interest is first deposited literally drop casted on the surface of the electrode to be modified ideally exclusively confined to the conductive electrode without. Spin Coating I Dropping on spinning substrate Film thickness.

In the present work drop-casting was used to prepare films for screening two-dimensional RuddlesdenPopper 2DRP metalhalide perovskite formulations for potential utility in PSCs without additional processing steps such as inert-gas blowing or. Drop-casting is a simple alternative method for film formation that is more closely aligned to industry-relevant coating processes. Thus drop-casting is more controllable than spray coating although its application is limited to small.

Check us out at www. Heating of the substrate to speed up the evaporation process andor improve film morphology. The drop shot may be the most versatile finesse technique in fishing.

All Answers 3 The solution mentioned by you spreads well on the glass slide. In a method for preparing a conductive polymer electrode by using drop casting conductive material is dispersed in a solvent to prepare a first mixture. Drop-casting is a simple alternative method for film formation that is more closely aligned to industry-relevant coating processes.

Drop Casting is the oldest from of jewelry making. Due to these advantages the drop-casting method has potential for industrial applications. Here are some of the most unique ways to present baits with this rig.

Avoid making a lot of false casts as this can spook the fish. In particular we note that the overwhelmingly popular approach for the preparation of PMEs is via the method of drop casting see Fig. Lift your rod to keep the fly high in the water column and then drop your rod tip.

Spin the chip on a spinner or. For small substrates 1 cm 2 an easy and tunable deposition method is drop-casting spreading a nanoparticle dispersion over a substrate and allowing it to dry under controlled conditions ie. Langmuir-Blodgett Spray coating.

Manuscript Generator Sentences Filter. This method is called as solvent casting because the polymer is completely soluble in the solvent which ensures uniform distribution hence fulfilling one of the ideal scaffold properties. You should completely fill up the glass slide with the solvent and then.

How to Execute the Drag and Drop Cast. This method is used for the formation of small coatings on small surfaces.

Linkasink B021 Ub Cast Bronze 16 Square Bronze Build Com Cast Bronze Bronze Sink Unlacquered Brass

Types Of Casting In Ipv6 Ipv6 Broadcast Ipv4

Sacchi Burlesque Drop Earrings Diamonds Gemstone 18 Karat Yellow Gold In 2022 Diamond Drop Earrings Drop Earrings Gold Earrings Dangle

Drop Casting Method To Screen Ruddlesden Popper Perovskite Formulations For Use In Solar Cells Acs Applied Materials Interfaces

Bc0095o Lost Wax Jewelry Fashion Eyeglasses Casting Jewelry

Drop Casting Method To Screen Ruddlesden Popper Perovskite Formulations For Use In Solar Cells Acs Applied Materials Interfaces

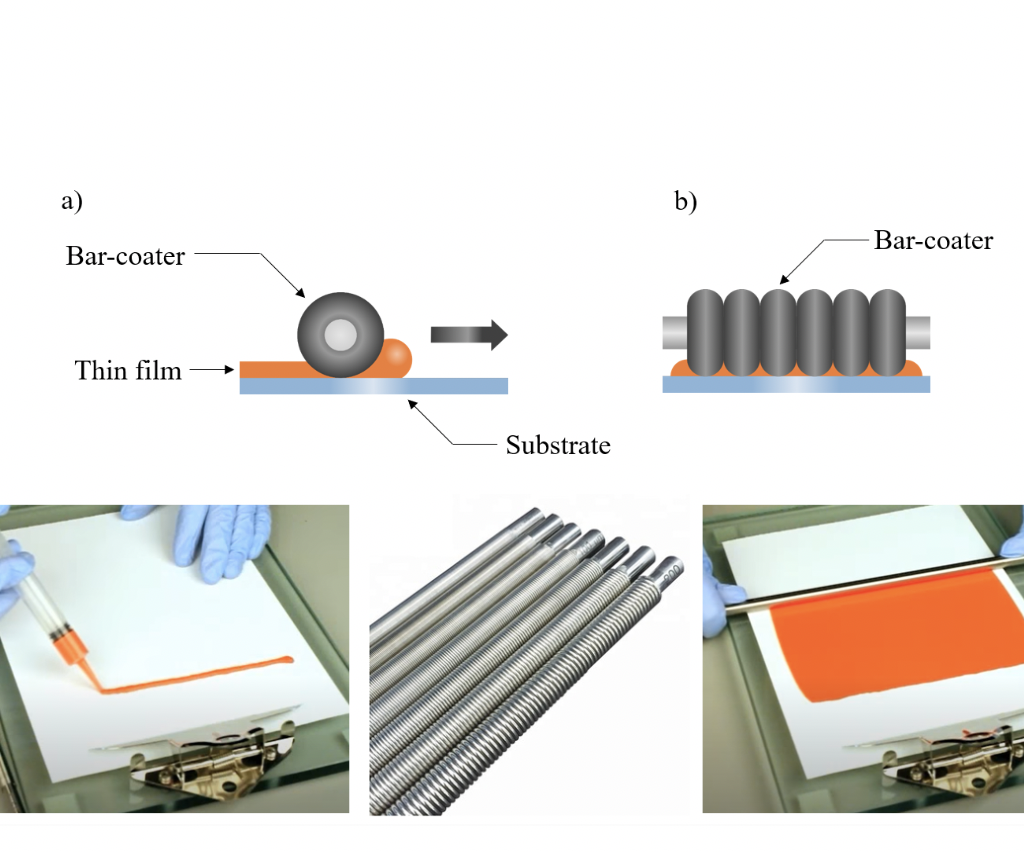

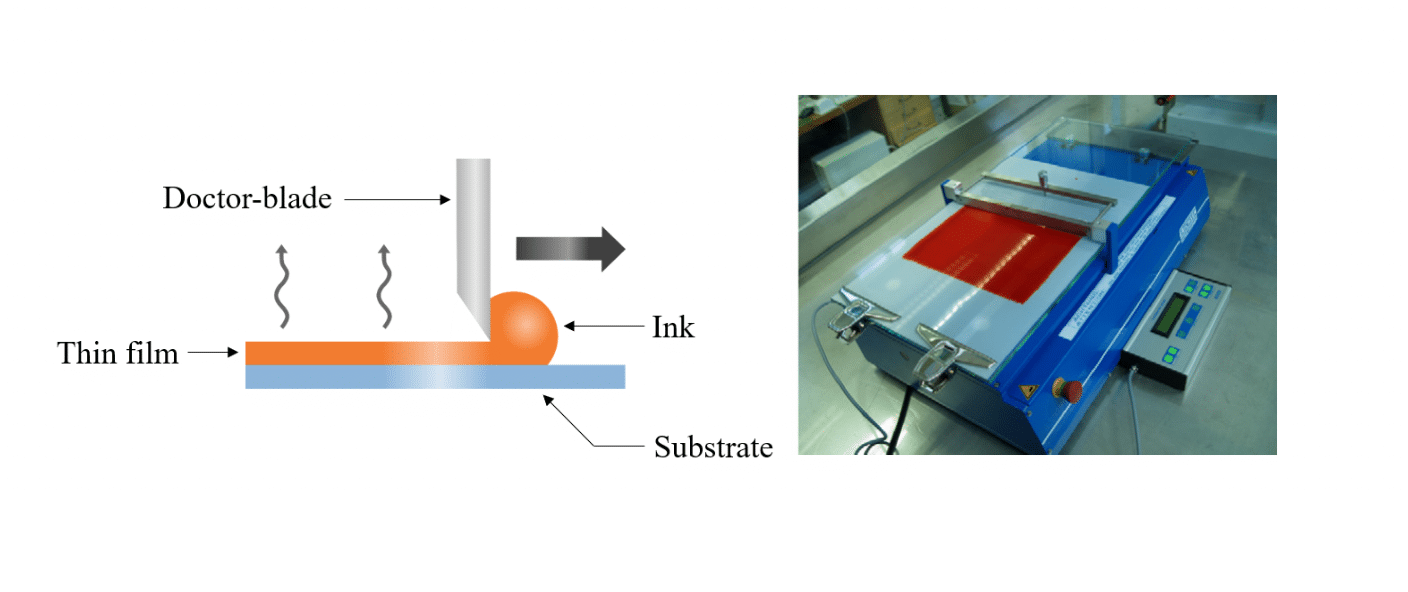

Thin Film Processing Method Part 1

Drop Casting Method To Screen Ruddlesden Popper Perovskite Formulations For Use In Solar Cells Acs Applied Materials Interfaces

Thin Film Processing Method Part 1

Small Black Cast Iron Cabinet Handle 3 Center To Center Cabinet Handles Black Cabinet Handles Iron Handles

Solvent Casting Technique Drop Casting Method Dip Coating Technique Film Casting Technique Polymer Coatings Technologies And Applications

Linkasink B035 Ub Cast Bronze 17 Circular Build Com In 2022 Unlacquered Brass Cast Bronze Bronze

Linkasink B019 Wb Cast Bronze 16 Square Bronze Build Com Cast Bronze Square Bathroom Sink Bronze Fixtures

Thin Film Processing Method Part 1

Linkasink Br001 Ub Cast Bronze 13 3 4 Circular Build Com Unlacquered Brass Undermount Bathroom Sink Bronze Sink

Sketch Of The Drop Casting Process Is Depicted Download Scientific Diagram

Fish Silicone Mold Fresh Water Bass Mould Resin Polymer Clay Etsy Silicone Molds Bass Fish Cake Fish

A Drop Shot For Speckled Trout Is An Excellent Choice When Fishing Deep Water Here S The Tried And True Method Fly Fishing Knots Drop Shot Rig Inshore Fishing

Comments

Post a Comment